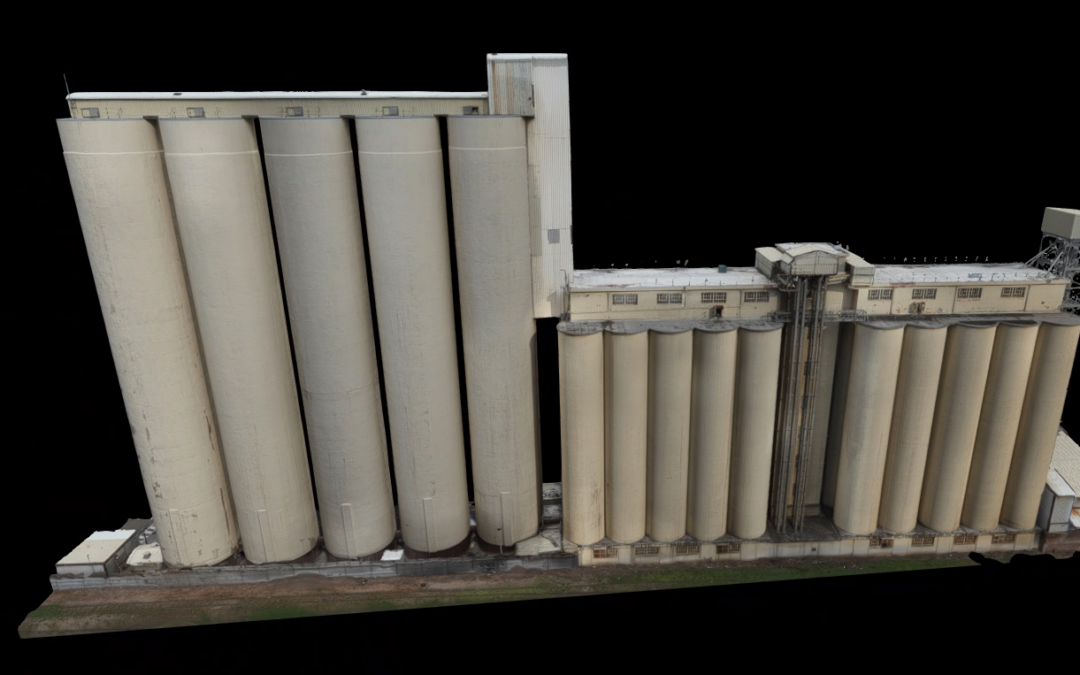

Durban Silo Array

Ending 2023 on a high note, Delta Scan conducted the phase 1 baseline visual inspection by digitising a Durban Silo Array in KwaZulu Natal.

Delta Scan took on the task of investigating the state of a Durban silo array through an internal and external inspection. The investigation covered a total of 35 silos and 16 inter-bins. The largest silo measured 60m in height and 10m in diameter. We captured, digitised, and inspected over 17,500 square meters of external façades and 17,500 square meters of internal façades.

Two teams dispatched for the task: an external team for photogrammetry and thermal data capture, and an internal team equipped with the Elios 3 for internal videography and SLAM LiDAR data capture. The external data capture took 2 days, while the internal data capture spanned over 5 days. Coordinated with the end-users planning team to ensure no disruption to work occurred.

Upon transferring the captured data to HQ, the team commenced work on creating the digital twin and initiating the inspection process. Utilizing our Hybrid AI approach, we can generate incredibly powerful façade maps. These serve as a roadmap for identifying the multiple observed defects and quantifying them.

Along with the external data, we were able to correlate and match external defects with internal defects. This isn’t possible with visuals alone, however, with our internal drones LiDAR capabilities we are able to showcase the observed defect on video on the precise location on the LiDAR map. This translates to the external 3D digital twin. Once again showcasing how far advanced Delta Scan is in inspection workflows and the meshing of different technologies. This ensures to our customers that they end up with the most in depth and powerful reports possible.

Project Details:

- Façade area inspected: 35 000sqm

- Time on site: 5 days

- Site Operating hours disrupted: 0s